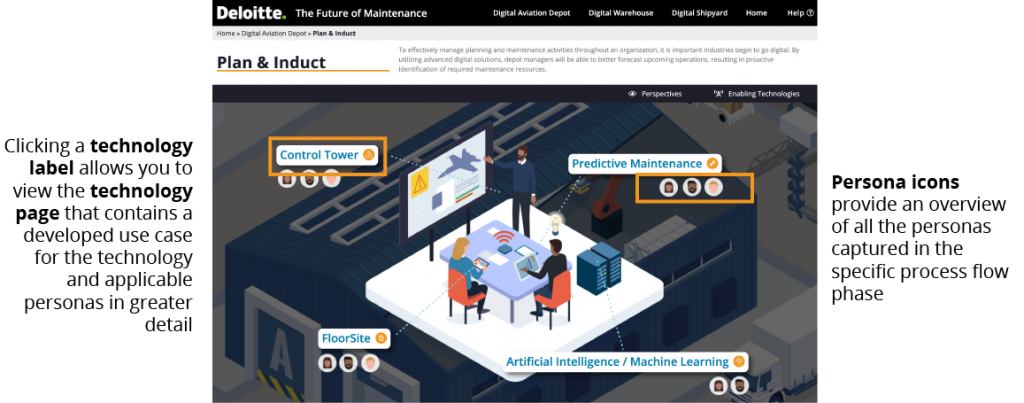

Repair & Overhaul

Various technologies provide engineers and artisans with solutions across the digital thread that accelerate maintenance and allow real-time operational feedback. Sensors tagged onto inventory racks/bins trigger automatic ordering when supplies are low. The digital twin provides a digital representation of past and current configuration and performance, enabling more efficient maintenance and increased informational awareness. Additive manufacturing allows artisans to create replacement parts and support tooling on-demand.