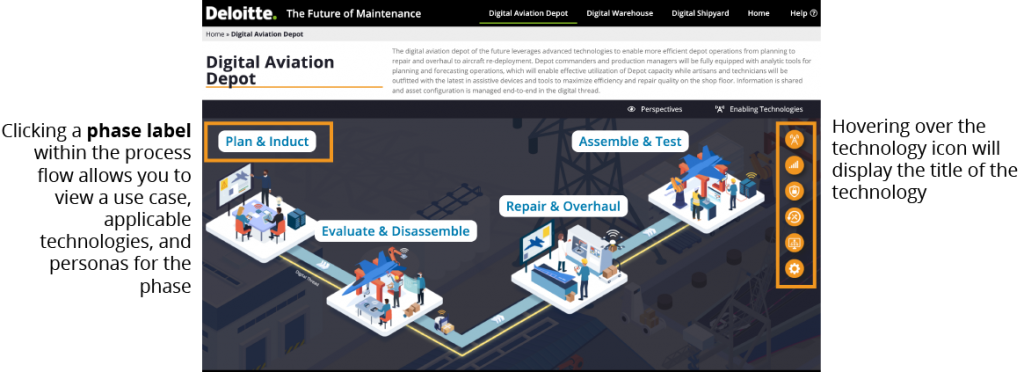

Evaluate & Disassemble

Various technologies provide depot floor workers with digital solutions that accelerate teardown and allow real-time operational feedback. The augmented reality headset provides the worker with step-by-step digital work instructions overlaid onto the physical environment to guide in the disassembly of the part of the plane they are working on. Scanning Quick QR codes ensures that the correct part is being removed. By placing the Internet of Things (IoT) sensors on the disassembled parts, the depot workers ensure that all parts and components that come off the plane are accounted for.