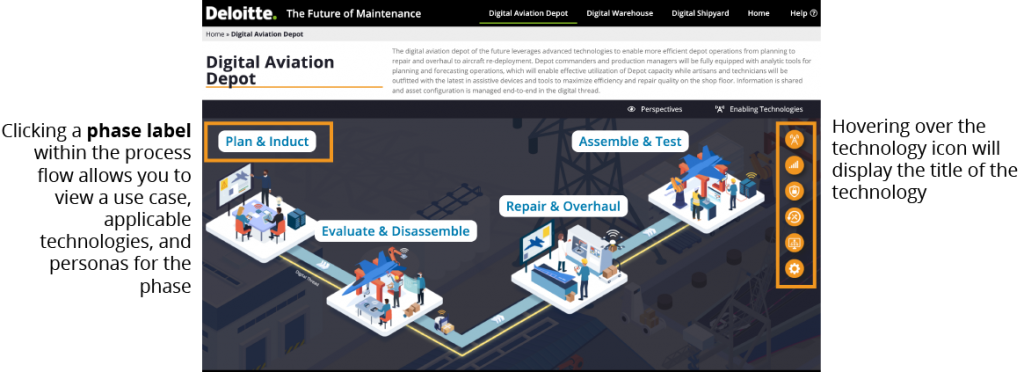

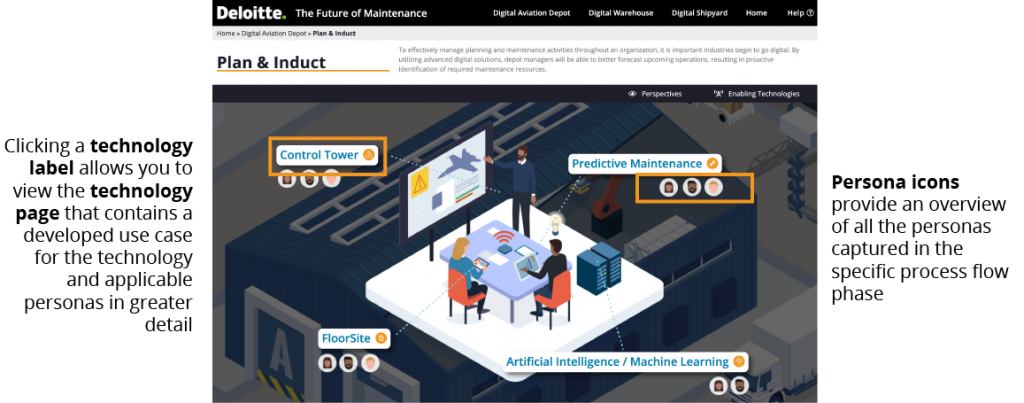

Home » Digital Aviation Depot » Plan & Induct

To effectively manage planning and maintenance activities throughout an organization, it is important industries begin to go digital. By utilizing advanced digital solutions, depot managers will be able to better forecast upcoming operations, resulting in proactive identification of required maintenance resources.

Contact Us | Supply Chain Management in Government | Privacy | Terms of Use | Cookies

Copyright © 2021 Deloitte Development LLC. All rights reserved.

As used in this document, “Deloitte” means Deloitte Consulting, LLP, a subsidiary of Deloitte LLP. Please see www.deloitte.com/us/about for a detailed description of our legal structure. Certain services may not be available to attest clients under the rules and regulations of public accounting.

This publication contains general information only and Deloitte is not, by means of this publication, rendering accounting, business, financial, investment, legal, tax, or other professional advice or services. This publication is not a substitute for such professional advice or services, nor should it be used as a basis for any decision or action that may affect your business. Before making any decision or taking any action that may affect your business, you should consult a qualified professional advisor. Deloitte shall not be responsible for any loss sustained by any person who relies on this publication.

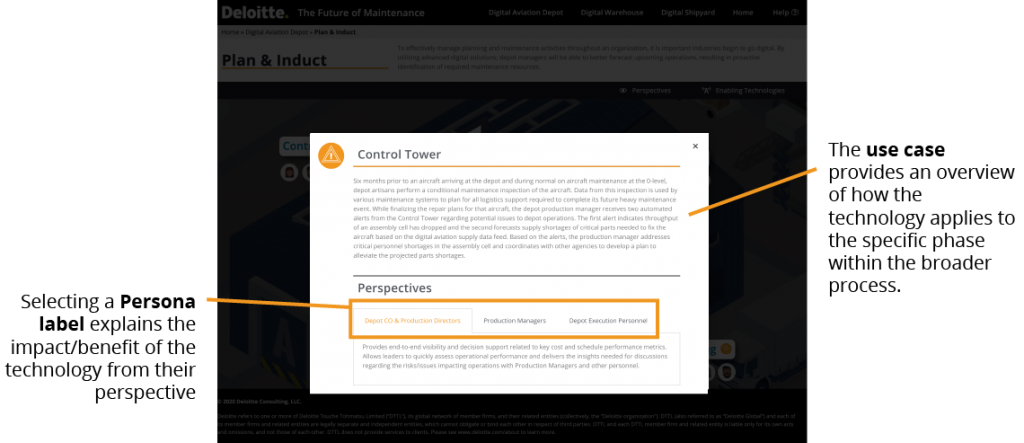

Six months prior to an aircraft arriving at the depot and during normal on aircraft maintenance at the 0-level, depot artisans perform a conditional maintenance inspection of the aircraft. Data from this inspection is used by various maintenance systems to plan for all logistics support required to complete its future heavy maintenance event. It also provides information to production managers concerning the amount of time as well as artisan skill sets required to perform that work. This information is used to determine proper staffing levels for future work. While finalizing the repair plans for that aircraft, the depot production manager receives two automated alerts from the Control Tower regarding potential issues to depot operations. The first alert indicates throughput of an assembly cell has dropped and the second forecasts supply shortages of critical parts needed to fix the aircraft based on the digital aviation supply data feed. Based on the alerts, the production manager addresses critical personnel shortages in the assembly cell and coordinates with other agencies to develop a plan to alleviate the projected parts shortages.

Want to learn more? Read more here: The Supply Chain Control Tower

Provides end-to-end visibility and decision support related to key cost and schedule performance metrics. Allows leaders to quickly assess operational performance and delivers the insights needed for discussions regarding the risks/issues impacting operations with Production Managers and other personnel.

Allows Production Managers to accurately plan for MRO activities through analysis of ongoing maintenance throughput and supply of parts. Notifications from the Control Tower allows Production Managers to pre-emptively act to avoid future bottlenecks and part shortages.

During routine operations, O-level maintenance reports decreased power output of an aircraft’s engine to the Fleet Support Team (FST) engineer. The FST engineer accesses the predictive maintenance reports to help determine the cause of this issue. Analyzing reports of aircraft with similar issues, it is determined that the aircraft has been experiencing higher than expected engine vibrations which has been shown to correlate with excessive wear on several critical components. Based upon this data, the FST engineer advises fleet personnel that the engine should be replaced via a Quick Engine Change Assembly (QECA). Once the engine is replaced, the aircraft mechanic scans the engines Quick Response (QR) code and the Aircraft Engine Management System (AEMS) is automatically updated with the new type, model and serial number information. Data portraying what organizational level maintenance tasks have been performed is compared to depot inspection results to identify potential organizational maintenance deficiencies. Those deficiencies are addressed via improved training or changes to maintenance tasking.

Want to learn more? Read more here: Predictive Maintenance and the Smart Factory

Based on various process improvements made to Depot operations, the production manager receives an automated recommendation from the depot’s Al/ML enabled planning software for increasing throughput for upcoming operations. Based on data from past maintenance operations, the software has recognized patterns and is able to identify the optimal induction and repair schedule for maximizing throughput of upcoming inducted aircraft. The product manager reviews the recommendations to confirm there will be no downstream impacts and accepts the recommendations. The production plan is updated automatically and approves the anticipated aircraft repair schedules prior to the aircraft arrivals. The revised aircraft delivery dates are communicated to the fleet customers who update aircraft deployment schedules accordingly.

Want to learn more? Read more here: Crafting an A.I. Strategy for Government Leaders

Once an aircraft arrives at the depot it goes through a disassembly phase and removed components are inspected during and after that phase in accordance with approved maintenance specifications. Pre- and post- inspection proximity sensors provide location and status data. Digital tag data integrated with an Electronic Work Instruction (EWI) ties technical drawings and specifications to work order operation lines and ensures components can be tracked and traced to the correct parent after teardown. As work order operations are completed, project status is updated and displayed on FloorSight dashboards to facilitate daily production meetings. Depot maintenance system to the Edge enables digital interaction via a mobile portal to provide end-to-end EWO status throughout the process.

Want to learn more? Read more here: Smart Sensors and Supply Chain Innovation

The digital transformation of the Nation’s depots, shipyard, and warehouses will leverage next-generation technology for everything from intelligent operations management and advanced manufacturing to digital supply network synchronization. Personnel at all levels will be better enabled to succeed in their roles through the introduction of these technologies. This digitally-transformed infrastructure will establish an architecture for the Navy to lead its mission readiness capabilities into the future.

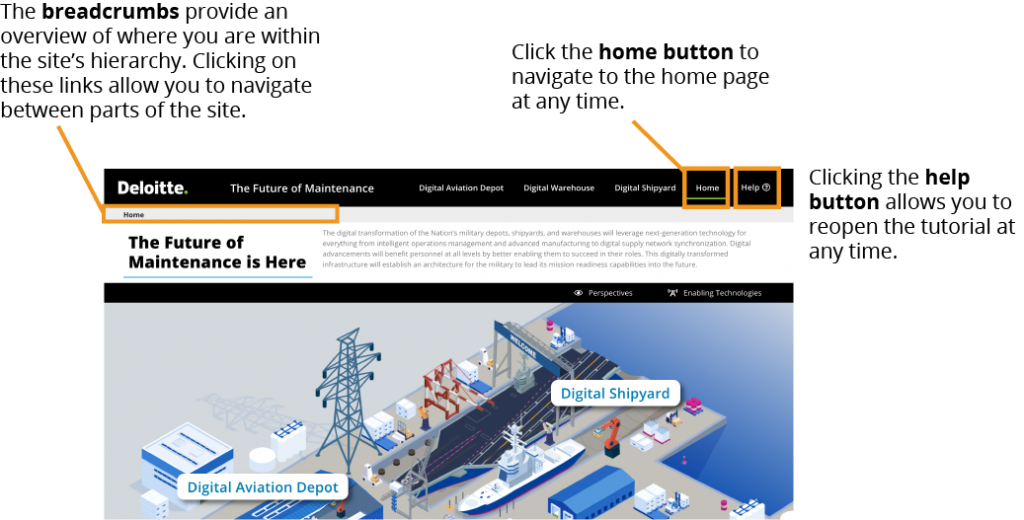

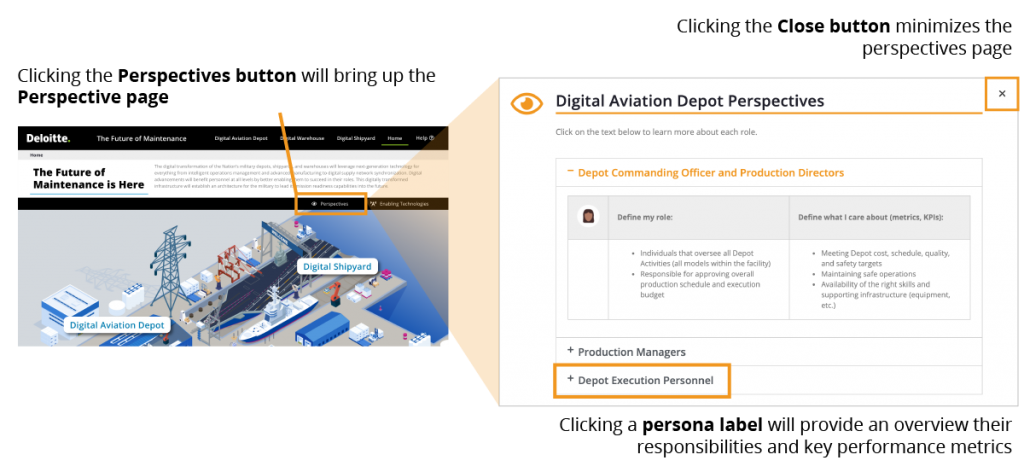

This tutorial will provide an overview of the Microsite’s functionality to understand the benefits and potential application of these technologies. Click on the slides below to learn how to navigate the site, otherwise close this window to start exploring. Site best viewed in Chrome or Edge browsers.

Click on the text below to learn more about each role.

| Define my role: | Define what I care about (metrics, KPIs): | |

|

|

| Define my role: | Define what I care about (metrics, KPIs): | |

|

|

1st Line Supervisors, Artisans, E&Es, and Quality Personnel

| Define my role: | Define what I care about (metrics, KPIs): | |

|

|

A key part of digital transformation of the Nation’s depots, shipyards, and warehouses are the enabling technologies that provide the foundation for the various technologies used throughout maintenance and logistics operations. These enabling technologies ensure connectivity, enable enterprise-wide visibility, and provide the security needed for system stability. Click on the text below to learn more about each role.

| A 5G network provides the connectivity that is essential when employing a broad web of interconnected technologies. A 5G network increases the speed of data transfer, lowers latency issues, increases the bandwidth capabilities, and increases the capacity of data that can be sent. |

| Cybersecurity supports the protection from cyber threats for all internet-connected systems such as the hardware, software, and stored data. Strong cybersecurity systems protect against unauthorized access to the sensitive information stored within military data systems. |

| A Product Lifecycle Management (PLM) solution integrates organizational data, systems, and processes. This allows artisans and depot managers to access the technical data and product specifications needed as well as create and monitor digital twins for repaired parts and weapons systems. |

| Model Based System Engineering (MBSE) solutions use a model based approach to support the setup of a complex system from initial concept to ongoing operational analysis. Using an MBSE approach supports orchestrating the combination of several complex systems and deepens the understanding of processes through integrated analytics. |

| Robotic and Intelligent Automation (R&IA) can drive efficiency across manual and repetitive processes. Automating tasks reduces back logs and creates time for staff to work on more value-add tasks. Given the large number of tasks that need to be performed across the shipyards, depots, and warehouses this will free up the artisans and managers to focus on higher complexity, higher value tasks. Automation can also drive analytics for leadership to make more informed decisions. |

| Control Tower provides deep supply chain data visibility through intuitive and innovative dashboards. Control Tower tools enable deep dives of data analysis to understand the reason for changes behind key performance indicators and augment problem solving and continuous process improvement. Control Tower capabilities can help proactively manage supply chains in real time, allowing leaders to focus on the most critical supply chain segments, while the rest of the supply chain can continue functioning in a business-as-usual fashion. A comprehensive Control Tower provides the visibility across the entire shipyard, depot, and warehouse to view the current state of all processes and quick identification of any pain points or areas requiring action by leadership. |